how to test water vapor permeability vendor|water vapor permeability in packaging : discount store MOCON provides Water Vapor Permeation Analyzers for testing water vapor & moisture transmission rate of films and packages for many applications. Call us today! WEBPrevisão do Tempo em Rosario Do Sul - RS, os próximos 14 dias, com as últimas previsões meteorológicos. Informações sobre precipitação, umidade, vento, temperatura.. Rio de Janeiro Estado do Rio de Janeiro 28. São Paulo Estado de São Paulo 24. Boa Vista Roraima 33. Florianópolis Estado de Santa Catarina 27. O tempo; Notícias .

{plog:ftitle_list}

WEBResultados de Exames Para acessar seus resultados de exames, entre com a identificação e senha disponíveis no seu cartão de exame. Acesso ao Cliente. Entrar como cliente. OU. Entrar como médico. Visualize as imagens dos seus exames pelo smartphone, computador ou tablet! Basta se logar e clicar no icone imagem, localizado dentro da .

water vapor transmission rate tester

Detailed video explanation of ASTM E96-22 standard desiccant and water test methods for water vapor transmission rate of materials. Two standard test methods are most common: ASTM F1249 (“F1249”) Standard Test Method for Water Vapor Transmission Rate Through Plastic Film and Sheeting Using a Modulated Infrared Sensor and ASTM E96 .MOCON provides Water Vapor Permeation Analyzers for testing water vapor & moisture transmission rate of films and packages for many applications. Call us today! How does climate impact permeability? In general, water vapor moves from the warm side of a wall to the cold side of a wall. This means that it tends to go from the inside out in northern climates and from the outside in .

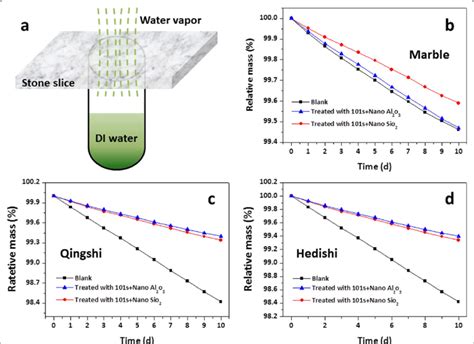

Yet another test method. Now, let’s look at how we test the permeance of a material using the ASTM E96 “standard test method for water vapor transmission of materials,” which is commonly known as a wet cup/dry cup . Cup experiments are the most widely used method to measure the water vapor permeability of porous building materials. For this test, cup assembly is designed to create a vapor pressure gradient across a sample and, thus, to allow vapor diffusion through it. Water vapor permeability is assessed by weighing cup assembly over time.Specific test methods for measuring water vapor permeability are given in ASTM Standard E96. For many engineering materials, vapor permeability is a strong function of mean relative humidity. Wet and dry cups cannot adequately characterize this dependence on relative humidity. Instead, a modified cup method can be used, in which pure water or .

Moisture vapor transmission rate (MVTR), also water vapor transmission rate (WVTR), is a measure of the passage of water vapor through a substance.It is a measure of the permeability for vapor barriers.. There are many industries where moisture control is critical. Moisture sensitive foods and pharmaceuticals are put in packaging with controlled MVTR to achieve the required . Five testing instruments plus a new test apparatus were employed to evaluate the water vapor transport properties of fabrics with low, medium, and high vapor permeability. The test results show that the desiccant inverted cup method generated the highest water vapor transmission rate, followed by the new method, the dynamic moisture permeation .Keywords: Water vapor permeability; Water vapor transmission rate; Cup method; Membrane; ASTM E96. 1. Introduction The global energy consumption has risen significantly in the past decades due to the growth of population, to the increase in the thermal comfort desire and to the rapidly developing economy. The study of permeation and diffusion of gases through polymeric matrices has been of great scientific interest for various applications such as packaging and development of membranes for separation [1, 2].Products such as food, medicines, electronics, photovoltaics, etc, are prone to degradation in the presence of water vapor [3, 4].Therefore, study of oxygen and .

The rate of water vapor transfer for fabric, coated fabrics, composite, clothing, industrial textiles, etc. is ascertained using the water vapor permeability test. Water Vapor Permeability Tester Equipped with a 500×500×500mm chamber and a customized air flue to regulate temperature, humidity, and wind speed, our machine typically comes with .FIELD MANUAL 110 Table 17-1.—A glossary of abbreviations and definitions used in permeability calculations K = Coefficient of permeability in feet (meters) per year under a unit gradient. Q = Steady flow into the well in ft3/sec [m3/sec]. H = The effective head of water in the well in feet (m). For packer tests, determining the effective head is defined For performance textiles, water vapor permeability is the focus, as it directly impacts the breathability of the fabric. So as a matter of fact, both breathability and permeability relate to a fabric’s ability to manage moisture, ensuring comfort and dryness during physical activities. . BSI – BS 3424-34 Method for testing the water .

Permeability of Common Building Material to Water Vapor. EEM-00259 View this publication in PDF form to print or download.. Order a hard copy. WHAT IS A PERM RATING? If a material has a perm rating of 1.0, 1 grain of water vapor will pass through 1 square foot of the material, provided that the vapor pressure difference between the cold side and the warm side of the . Load the test sample onto the test cup. The water vapor permeability tester places the positive cup in the test apparatus. After equilibrating, weigh the object to obtain its initial weight. Then, testers test and weigh it again. The formula uses the mass difference from the second weighing. It uses the difference to find the sample’s .

The water vapour permeability of the fabric is the loss in weight of water in the cup, expressed in g/m2/day. Since the water vapour permeability is influenced by the still air layer resistance below the fabric, which dominates the total resistance and .

Water vapor transmission is a rather confusing issue. The difference in vapor pressure between two sides of a building envelope assembly is the driving force behind vapor transmission. (Although by comparison, gaps .

After the test a μ-value can be evaluated according to equation (1) (derived from Fick’s law). a p g d GP ˜' ˜ (1) where: μ - water vapour resistance factor (-) įa - water vapour permeability of still air (kgÂ

What is water vapor transmission or WVT, the Water Vapor Permeance or WVP, and the Water Vapor Permeability? These three terms are used to describe how quickly water vapor diffuses through a solid material. The .By studying various test methods of water vapor transmission rate, Labthink manufactures many water vapor permeability testing instruments based on ASTM E96/GB 1037 (gravimetric method), ISO 15106-2/ASTM F1249 (infrared sensor method), ISO15106-3 (electrolytic sensor method) and ISO15106-1/ASTME398 (humidity sensor method). Labthink has the . 2.4.Water vapor permeability (WVP) determinationThe apparatus and methodology described in the ASTM E96 (ASTM, 1995) were used to measure the WVP of the film.Film specimens were conditioned for 48 h in a chamber at 25 °C and 52% relative humidity (Mg(NO 3) 2 saturated solution) before being analyzed. Films were sealed on cups containing .for water vapor it is given in units of mass of water vapor. Sometimes, the amount of permeant is given in moles. Sometimes the term “diffusion coefficient” is used incorrectly instead of permeability, which are different properties, leading to additional confusion. Another complication involves the water vapor transmission rate (WVTR).

Discover the importance of water vapor permeation testing. Ensure the barrier properties of packaging materials. Learn why water vapor permeation testing matters.

water vapor transmission rate test

The round robin test of the water vapor permeability showed a considerable variations of the determined values. It shown that the finished leather has a standard deviation of 22.3% and 10.4% for . This video explains the test method ASTM E96 for determining the amount of water vapor that will diffuse through a material in the presence of vapor pressure.

Water vapor permeability is a measure of the passage of water vapor through a material. It is also known as water vapor transmission rate (WVTR) or moisture vapor transmission rate (MVTR) - which is basically the mass of water vapor that is transmitted through a measured area in a specific unit of time under specified conditions of temperature and humidity.ASTM D 1653 is a standard test method used to determine the permeability of organic coatings to water vapor and gases. The test involves immersing coated test panels in water or other liquids, and measuring the rate of water vapor or gas transmission through the coating.Lab Asphalt Permeability Testing; Field Permeability Testing of Pavement; Calculating the Coefficient of Permeability; Asphalt permeability has a direct impact on the performance and longevity of pavements. Long-term internal exposure to water and water vapor in the asphalt voids is a significant factor in the premature deterioration of roadways. which in turn prompts the popularization of relevant testing items. At present, gas permeability test and water vapor permeability test of materials have become rather popular. Generally, each index of barrier property can be tested with several test methods. These methods differs to some extent in their testing principles, thus affects the .

the importance of torsion test in engineering

webPokoje. Do dyspozycji gości udostępniamy aż 228 jednoosobowych i dwuosobowych pokoi w Warszawie. Elegancki wystrój i funkcjonalne wyposażenie odnajdą Państwo w standardach: LUX, PREMIUM LUX, oraz STUDIO. Każdy pokój wyposażony jest w: telewizor, telefon, zestaw do parzenia kawy i herbaty. oraz suszarkę. Dodatkowo pokoje PREMIUM LUX .

how to test water vapor permeability vendor|water vapor permeability in packaging